Treated Ply Bridge and Wharf Decking

NiuDeck

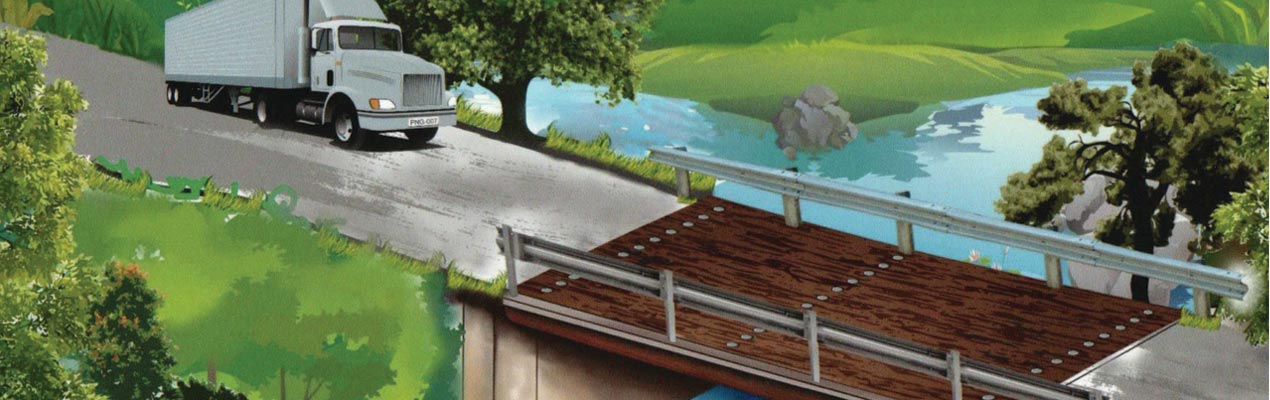

NiuDeck is a purpose designed and engineered heavy plywood decking system which is primarily used for re-decking traditional timber bridges but can also be used with steel supporting structures including wharf and rail deck applications.

Manufactured using proven durable glue system together with 100% veneer preservation treatment method, the product is well designed for the adverse climatic conditions of bridge applications ensuring a long design life.

Developed as a renewable alternative to traditional hardwood sawn timber NiuDeck is manufactured from sustainable plantation pine using hydro-electric power to the highest quality standards.

Available in a range of thicknesses NiuDeck offers the engineer a cost effective solution for a wide variety of application which comply with either, Austroads Bridge design Code or Australian standard AS5100 Bridge design.

In addition a custom design service is available to handle the most challenging applications.

Preservation Treatment

Preservative TreatmentNiuBridge and NiuDeck utilized the veneer preservation treatment method to ensure complete protection from termites and fungal decay (rotting). Veneer treatment is the only way to ensure complete penetration and any unsealed cut panels will not decay.

Veneer treatment method is where the individual sheets of veneer are preservative treated with Alkaline Copper Quaternary (ACQ) to Hazard class H4 (in ground protection) before being fabricated into plywood to ensure 100% penetration. The treated veneers are then bonded with a permanent phenolic resin which is often referred to as “A” bond or Marine “A” or Structural bond.

Structural “A” bonds require rigorous testing after submersion in boiling water for 72 hours or 6 hours under high pressure steam to ensure a high quality bond.

Deck Wearing Surface

NiuDeck requires a durable deck wearing surface to be installed to ensure that the designed service life is achieved. In order to maximise the life of the deck wearing surface the entire bridge structure must be tight to minimise movement under load.

NiuBridge and NiuDeck utilized the veneer preservation treatment method to ensure complete protection from termites and fungal decay (rotting). Veneer treatment is the only way to ensure complete penetration and any unsealed cut panels will not decay.

Veneer treatment method is where the individual sheets of veneer are preservative treated with Alkaline Copper Quaternary (ACQ) to Hazard class H4 (in ground protection) before being fabricated into plywood to ensure 100% penetration. The treated veneers are then bonded with a permanent phenolic resin which is often referred to as “A” bond or Marine “A” or Structural bond.

Structural “A” bonds require rigorous testing after submersion in boiling water for 72 hours or 6 hours under high pressure steam to ensure a high quality bond.

Advantages

- Manufactured to a minimum stress grade of F14

- Light weight

- Reduced installation time

- Compliant to AS5100 Bridge Design standard

- Flexible design options

- Custom design service

- Reliable engineering properties

- Facilitates bridge widening by cantilevers

- Sustainable high strength plantation resource

- ACQ H4 “Veneer Treatment” preservation

McKanes Fall Bridge, over Cox’s River 7km south of South Bowenfels, NSW.

NiuDeck plywood panels of 155mm thickness were used in the refurbishment of this heritage timber truss bridge, by NSW Roads & Maritime Services in early 2021.

This preservative treated plywood panelling is unique, in that it is high strength and preservative treated throughout, not only having a penetrated envelope of the outer veneers.